U.S. Energy Dept. Report Compares Energy and Environmental Impact of Lighting

投稿人:电子产品

2012-10-02

LED lighting suppliers are quick to claim that their products are more environmentally friendly than alternative technologies. The makers point to the inefficiencies of incandescent bulbs and the mercury content of compact fluorescent lights (CFL) as examples to support their case.

But are these claims just marketing bluster? A new report from the U.S. Department of Energy seeks to address just this question. The report is broken down into three parts that review lifetime energy consumption, environmental impact of manufacture and disposal, and the environmental impact of hazardous substances used in the assembly of LED luminaries, CFLs, and incandescent bulbs.

A question of efficacy

To produce the report,¹ Pacific Northwest National Laboratory, on behalf of the U.S. Department of Energy, reviewed existing life cycle assessment (LCA) literature to determine the range of energy consumption and downstream energy savings promised by LED lighting. The report compared life cycle energy consumption of a 12.5-W LED luminaire to a 15-W CFL and a 60-W incandescent lamp based on 10 literature studies. The three types of light each produced about 850 lm.

The results took into account the energy required to manufacture the lamp, transport it, power the device for 20 million lumen hours, and then dispose of the device.

Intriguingly, it turns out that solid-state lights and CFLs consume the same amount of energy during their lifetime, at around 3,900 MJ. This is despite the fact that, in operation, LEDs are more efficient than CFLs. Cree’s popular ML-C white LED, for example, has an efficacy of 91 lm/W, while OSRAM’s warm white OSLON SSL LED measures up at 100 lm/W. In comparison, the typical efficacy of a CFL is between 35 and 60 lm/W.²

Perhaps not surprisingly, considering their low efficacy (around 10 to 18 lm/W), incandescent bulbs perform badly, consuming around 15,100 MJ during their lifetime.

The equality between the energy consumption of LEDs and CFLs over the products’ entire lifetimes is even more surprising considering that the energy required to light the lamp is by far the biggest contributor to the energy budget. The next biggest contributor is manufacturing, with a negligible addition from transportation (at less than one percent of the total energy consumption).

(It should be noted that estimates of the energy consumption used during manufacture are somewhat uncertain, with the estimates in the surveyed literature ranging from 0.1 to 27 percent of the total life-cycle energy consumption.)

Environmental impacts

Although energy consumption is a vitally important consideration when selecting a lighting technology to minimize environmental impact, there are other criteria that should be examined. For example, the manufacture and disposal of a lighting technology has an impact on natural resources and the cleanliness of the ecosystem and should be therefore be taken into account.

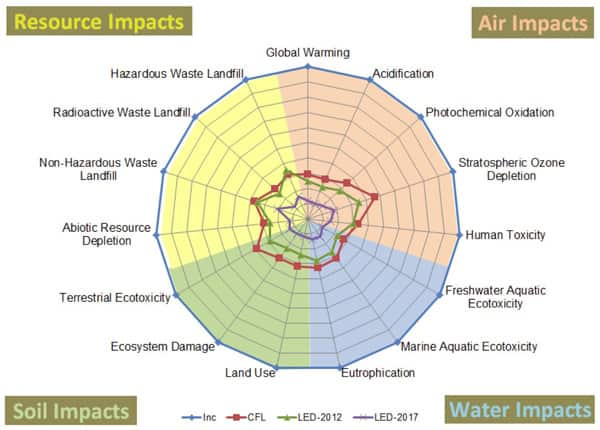

The authors of the report compared the impact of each technology by evaluating 15 “impact measures” in four areas: resource, air, water, and soil. The impact measures were each represented by a spoke on a “spider” graph with the relative impact of each measurement determining its magnitude on the graph.

The worse performing technology (incandescent lighting) was used as the baseline and the other products were then normalized to that scale with a greater impact indicated by plot further from the center of the graph. In other words, light sources with the least impact will appear closer to the center. The data plotted in the graph, shown in Figure 1, are normalized for the quantity of lighting service, measured in lumen-hours. The graph features an additional technology, LED lighting in 2017, which takes into account the fact that further improvements are likely to occur in LED manufacturing, performance, and driver electronics by then.

Figure 1: Impact measures on the environment caused by lighting technologies. (Courtesy: U.S. Department of Energy.)

From the figure, it can be seen that LED and CFL technology have a much lower impact per unit lighting service than incandescent bulbs. The phrase “impact per unit lighting service” means that the performance of the technology in the graph is not a function of the material content of a single lamp, otherwise the incandescent lamp would appear better because it has the lowest material content and is the least complex lighting system.

Rather, the incandescent bulb’s performance is so poor because of its efficacy as a light source, meaning it consumes large quantities of energy to produce light and many replacement bulbs are required to span the (much longer) rated life of a single LED lamp or CFL. This large energy consumption causes substantial environmental impact. This is also the primary reason why many governments are mandating the elimination of incandescent bulbs for domestic use.

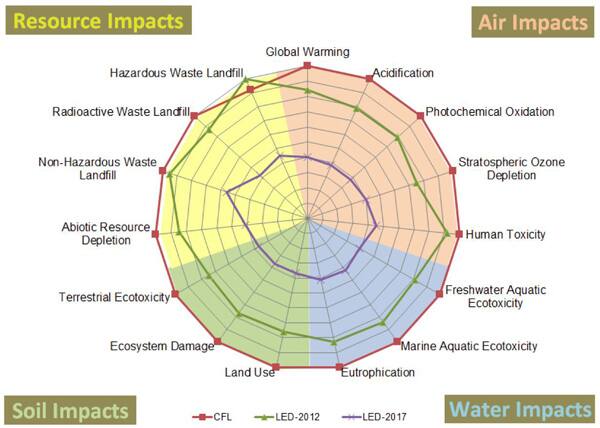

Figure 2 takes a closer look at how LEDs and CFLs compare by removing the incandescent bulb and normalizing to represent the impact relative to the CFL.

Figure 2: Impact measures on the environment caused by LED and CFL lighting technologies. (Courtesy: U.S. Department of Energy.)

It can be seen that CFL is slightly more harmful than the 2012 integrally-ballasted LED lamp against all but one criterion – hazardous waste landfill – where the manufacturing of the large aluminum heat sink typically used in the LED lamp causes its impact to be slightly greater for the LED lamp than for the CFL.

The best performing light source is projected to be the LED lamp of 2017, which will benefit from improvements in manufacture and performance.

LEDs come out on top

The horribly inefficient incandescent bulb is, quite appropriately, about to be consigned to history and the prospective replacements, LEDs and CFLs, are much more environmentally sympathetic.

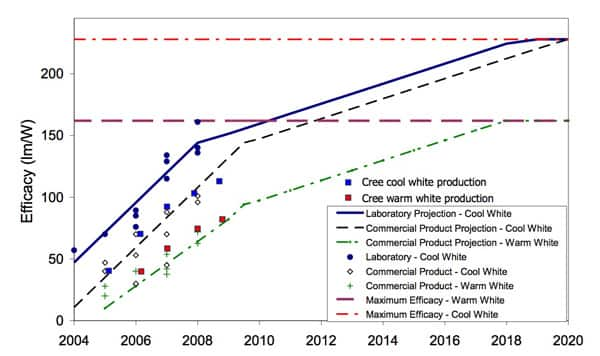

In terms of energy consumption over the product’s life, despite the greater efficacy of LEDs, there is little to choose between the technologies. However, LEDs are still an immature technology and companies such as Cree, OSRAM, and Seoul Semiconductor are spending millions of dollars to improve and refine their products. (See the TechZone article “LED Efficacy Improvement Shows No Sign of Slowing.”)

Cree, for example, announced its latest XB-D range in January 2012. The company says the LED delivers up to 139 lm and 136 lm/W in cool white or up to 107 lm and 105 lm/W in warm white (at 350 mA and 85°C). Similarly, OSRAM has released its OSLON Square device (Figure 3) that is said to produce 134 lm/W in its cool white form (at 700 mA). For its part, Seoul Semiconductor offers the STW8Q14B, a surface mount 35-lm chip that boasts an efficacy of 109 lm/W (at 100 mA).

Figure 3: The OSLON Square LED from OSRAM produces up to 134 lm/W.

Further improvements in efficacy would lower the heat production of LEDs and allow the aluminum heat sink to shrink, addressing the only area where CFLs outperform LEDs – hazardous waste to landfill. The impact of the heat sink is mainly as a result of the upstream energy and environmental impact from the manufacturing of the aluminum from raw materials. Improved recycling efforts could also reduce the adverse impact of manufacture.

Fast-forwarding to 2017, will see LEDs leap ahead as technological improvements, especially in efficacy (Figure 3), resulting in a reduction of solid-state lighting’s environmental impact to about 50 percent lower that today’s LEDs and 70 percent lower than CFLs.³

Figure 4: Projected advances in LED efficacy will lower environmental impact. (Courtesy of Cree)

References:

- “Life-Cycle Assessment of Energy and Environmental Impacts of LED Lighting Products,” U.S. Department of Energy, June 2012.

- “Energy Efficiency of White LEDs,” U.S. Department of Energy, June 2009.

- “Demonstrating the Next Wave of LED Chips and Packaging Improvements,” Cree, DOE Solid State Lighting Workshop San Francisco, February 2009.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国