Light Sensors: An Overview

投稿人:电子产品

2012-09-11

Light sensors detect light and convert light energy to an electrical signal output. Once converted into electrical energy, the radiant energy within the infrared to ultraviolet light frequency spectrum source can then be measured.

One recent but now almost overriding application of light sensors is in LCD Backlight Control. Here, ambient-light sensor ICs are designed to detect brightness over a wide range, from darkness to direct sunlight, and output the data in order to adjust LCD brightness for optimum visibility and lower power consumption.

Another variety of light sensor, photoelectric sensors, consists of devices used to detect the distance, absence, or presence of an object by using a light transmitter (usually infrared) and a photoelectric receiver. Photoelectric sensors are employed in commercial and residential lighting, as well as in security applications.

These and other light sensors fall into two main categories. The first group generates electricity when illuminated and is known as either photovoltaic, converting solar radiation into direct-current electricity, or photo-emissive, which releases free electrons from a light sensitive material such as cesium when struck by a photon of sufficient energy. The second grouping includes those that change their electrical properties in some way, such as a photoresistor (whose resistance decreases with increasing incident light intensity) or a photo-conductor (which varies electrical resistance when subjected to light).

Devices in these two broad categories can be further subdivided into these classifications:

- Photoconductive cells

- Photo-junction devices

- Photovoltaic cells

Photoconductive cells

In a photoconductive light sensor, material becomes more electrically conductive due to the absorption of electromagnetic radiation such as visible light, ultraviolet light, infrared light, or gamma radiation. Photoconductive cells consist of a thin single-crystal or polycrystalline film of compound semiconductor substances. Most commercially available photoconductive cells are manufactured from cadmium sulfide (CdS), which is sensitive to light in the visible spectrum. Other examples of photoconductive materials include the conductive polymer polyvinylcarbazole, used extensively in photocopying (xerography), lead sulfide (PbS), used in infrared detection applications such as heat-seeking missiles, lead selenide (PbSe) and lead telluride (PbTe).

The photoresistor, a semiconductor device that uses light energy to control the flow of electrons as well the current flowing through them, is the most common photoconductive device. CdS photoconductive cells are often referred to as light-dependent resistors (LDR). They function within the same general spectral range as the human eye and are therefore widely used in applications where this type of spectral response is required. The resistance of the cell when not illuminated is very high (about 10 MΩ), but drops to about 100 Ω when fully illuminated.

An example of an LDR is the Omron Photomicrosensor (Transmissive) EE-SH3 Series, available as a high-resolution part with a 0.2 mm or 0.5 mm wide sensing aperture, a high-sensitivity model that can detect 1.0 mm diameter objects, and a model with a horizontal sensing aperture. The sensor uses a center mark for simplified optical-axis adjustment, and incorporates soldering terminals (EE-SH3) or PCB terminals (EE-SH3-B). Solder terminal models and PCB terminal models also are available.

LDR photoconductive cells improve conductivity with a decrease in resistance for an increase in illumination. The cells take several seconds to respond to a change in light intensity.

Photo-junction devices

In contrast, photo-junction devices are light sensors or detectors made from silicon semiconductor PN-junctions that are sensitive to light. Photo-junction devices are designed for detector application and light penetration with their spectral response tuned to the wavelength of incident light. They detect both visible and infrared light. These devices include photodiodes and phototransistors.

Photodiodes are similar to a PN-junction diode, but the outer casing is either transparent or has a clear lens to focus light onto the PN junction, increasing sensitivity. The junction responds to red and infrared longer wavelengths.

Vishay’s TEMD1000 series of PIN photodiodes (Figure 1) feature high speed and high radiant sensitivity in black, surface-mount plastic packages featuring a lens and daylight blocking filter matched with 870 to 950-nm IR emitters.

Features of the four-part series include:

- Package form: GW, RGW, yoke, axial

- Dimensions: 2.5 x 2 x 2.7 mm

- Radiant sensitive area (in mm²): 0.23

- Fast response times

- Angle of half sensitivity: φ = ±15°

When light falls on the junction, a greater number of hole/electron pairs are formed, increasing the leakage current. The current is directly proportional to light intensity falling onto the PN-junction. An advantage of photodiodes is their rapid response to changes in light levels. They have a relatively small current flow, however, even when fully lit.

Another photo-junction sensor is the phototransistor, which is a photodiode with amplification. It operates in the same way as a photodiode, but provides current gain and greater sensitivity. Phototransistors have currents that are 50 to 100 times greater than standard photodiodes.

Photovoltaic cells

The most common photovoltaic light sensor is a solar cell that converts light energy into DC electrical energy in voltage or current. Photovoltaic cells work best using the sun’s energy, and applications include calculators and satellites.

Made from single-crystal silicon PN junctions, a photovoltaic cell has a very large light sensitive region. Light energy causes electrons to flow through the PN junction. An individual solar cell can generate an open circuit voltage of approximately 0.48 V.

The amount of available current from a solar cell depends on the light intensity, the size of the cell, and the cell’s efficiency. Using polycrystalline silicon or amorphous silicon increases efficiency.

Solar cell use is seen in the IXOLAR High Efficiency SolarBIT (Figure 2) product line of monocrystalline, high-efficiency solar cells. These devices are used for charging various battery-powered and handheld consumer products such as mobile phones, cameras, and power backup for UPS, sensors, and wearables. Industrial applications include usage in wireless sensors, portable instruments, and backup-battery charging.

Their advantage is in the ability to extend runtime, even in low-light conditions and increase battery life and runtime in a small footprint.

IXYS has characterized the moisture reflow sensitivity of the SolarBIT using IPC/JEDEC standard J-STD-020. Moisture uptake from atmospheric humidity occurs by diffusion. SolarBITs are shipped in 460 mm long, clear PVC carrier tubes with antistatic coating.

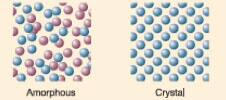

Solar cells are classified according to the material used. Amorphous refers to objects with no definite shape. Unlike crystal silicon where the atomic arrangement is regular, amorphous silicon features irregular arrangement.

An example is the Sanyo Amorphous Photosensors, silicon solar cells and photosensors that feature Silane (SiHa4) as the source gas and fabricated using a plasma CVD method. Three silicon layers, the P layer, I layer, and N layer, are formed consecutively on a glass substrate. The PIN- junction corresponds to the P/N junction of a crystal silicon solar cell.

In amorphous silicon (Figure 3), the reciprocal action between silicon atoms and photons happens more frequently, so more light is absorbed. An ultra-thin amorphous silicon film of <1 µm can be produced and used for power generation. With a metal or plastic substrate, flexible solar cells can be manufactured.

As indicated in Figure 4, these sensors can be used in several applications.

This article has examined several types of light sensors and presented representative examples. For more information on the products mentioned, click on the links provided to access product pages on the DigiKey website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国