LEDs Remain the Most Ergonomic Type of Display for Industrial Measurement and Process Control System

投稿人:DigiKey 欧洲编辑

2013-02-05

This article illustrates the uses of LEDs in industrial measurement and process control systems by referencing specific products available through DigiKey from various manufacturers. This includes a number of the basic types of LED components (single LED indicators, multi-segment bar and alpha-numeric displays) that might be used in original equipment designs (from Lumex, Lite-On, and Avago) and a ready-to-go display solution from Matrix Orbital.

Introduction and background perspective on LED displays

Few would argue against the premise that LEDs are ubiquitous devices, but they have come a long way in the past 50 years since the first visible light LED was invented. For many years, LEDs were used for little more than indicator lights. They were predominantly red, although green and yellow versions later became popular, allowing a stop, go, and caution meaning to be attributed to their use. While LEDs can compete with neon indicators in mains powered equipment, it was almost certainly their ability to operate at lower voltages that facilitated their widespread adoption in a multitude of electronic systems, from professional equipment through to consumer products. Relatively speaking, LEDs were also low-power devices, so they were also favored in battery-powered designs.

Single LEDs were essentially status or threshold indicators, i.e. on/off or “low battery”, but their ease of use quickly saw applications where multiple LEDs were arranged to provide displays mimicking analog meters or thermometer-style gauges, such as volume or recording level indicators in consumer audio equipment. In some instances, there was a novelty aspect to such designs as the coarse granularity of their measurement hardly compares with the meters or gauges they replace. Where they often win out is in providing a bold, bright, easy to read display when absolute accuracy or greater resolution is not required. Equally, the intrinsically rugged nature of solid-state LED technology suited portable applications, where delicate analog meters could be easily damaged and therefore prove unreliable.

The use of multiple LEDs, as described above, rapidly led to the development of specific LED bar-graph displays with a number of LEDs encapsulated in a single, dual-in-line package. Apart from displaying pseudo-analog level information, these were often used as ‘progress’ indicators in process control systems. From here it was a short step to arranging LEDs in a package to create 7-segment numeric and 16-segment alphanumeric character readout displays. Prior to this, electronic character displays used ‘Nixie’ tubes, but these were typically limited to early digital instruments, such as voltmeters and frequency counters, and certain public display applications in clocks, elevators, and departure boards.

Consequently, this simple evolution in LED display technology, coupled with the digital revolution that was happening at that time (we are talking of the late 1970s here), saw an explosion in the use of LED character displays. These saw the demise of ‘Nixie’ tube applications, but more significantly, spawned many new applications, especially in consumer products such as LED digital watches and calculators and other products around the home such as microwave ovens and video recorders. Clearly, size and cost were also factors in this booming use of LEDs, enabling designs that were not previously practical or cost-effective.

Since then, we have seen LED displays superseded by newer, alternative technologies in a number of areas and for a variety of reasons. Liquid crystal displays (LCDs) were quick to replace LEDs in watches because low power, reflective TN LCDs meant the display was always visible without pressing a button. Similar, “always-on” battery-powered devices also adopted LCDs, while mains-powered equipment typically favored vacuum fluorescent displays (VFDs) that offered bright, multi-character displays in various colors, which were attractive and more readable than the monochrome LCD technology of the time.

Technology does not stand still, however, and LEDs, LCDs, and VFDs have all improved markedly in the last three decades. Each technology has its pros and cons for different applications, but these also depend on the target market for its potential volume. At one end of the spectrum, color LCD panels (albeit increasingly with LED backlighting) dominate the television and computer display market. Conversely, for simple indicators, LEDs remain king. In between, the choice for multi-segment bar, character, or other graphical display is more complex. Without a doubt, VFDs offer a highly customizable solution that can incorporate alphanumeric characters with other symbols, indicators, and bar-graph style readouts. But such dedicated customization is typically only warranted for high volume applications such as automobile dashboards or consumer appliances. For lower volumes, where bright, highly visible, easy-to-read displays are required, the design flexibility offered by LEDs is unbeatable, as we will see in the industrial data acquisition systems considered below.

Why choose LEDs for industrial measurement and process control displays?

Industrial measurement and process control systems come in all shapes and sizes, so it is impossible to generalize. Some will be highly computerized, with data captured remotely for display on a regular computer screen, or perhaps using a dedicated program that also provides a control interface. Other systems, such as that shown in Figure 1 below, may be more traditional, featuring dedicated indicators, displays, and controls.

Figure 1: Industrial process controls need to display data simply and clearly.

While the latter type of measurement and control interface appears less sophisticated than a computerized solution, it may simply be more conservative by design. Considerations of safety, security, and reliability can also dictate the use of a hard-wired solution. Ergonomics, often referred to as ‘the human factor', is another very strong design influence. The image in Figure 1 typifies this approach, where a number of identical pieces of equipment are individually monitored and controlled. The primary benefit here is the one-for-one relationship between the equipment and its measurement and control interface, so there is no switching or multiplexing of signals, to or from the equipment.

Having established the need for a measurement and control system using a dedicated interface, the design process then needs to look at what data need be displayed, how the process is to be controlled, and what feedback is needed to confirm control operation and status.

Control status indicators

Controls can take the form of switches, dials, and pushbuttons, and may also operate directly on the circuit or signal concerned or indirectly where, for example, a low-voltage control system might operate a relay that in turn switches on the power to a pump or motor. Direct controls will be electro-mechanical devices, ranging from simple on-off switches through multi-position rotary or slider switches, but also including dial or slider potentiometers. The nature of many of these devices means that their status may be apparent from their position, as is usually the case with, for example, a toggle switch. This may be fine for a prominently positioned switch in a well-lit location, but for many applications, the provision of a status indicator is generally expected. And certainly with indirect controls an indicator becomes much more desirable, especially if the requirement is to show the actual status of a remote device. Indeed this requirement is more akin to simple data monitoring and little different to displaying a threshold measurement such as ‘low battery’.

The characteristics on an indicator will of course depend on the application and the environment where it is deployed. The layout of the control panel is also vitally important to ensure the indicator is correctly associated with the right control. This may be achieved by simple physical proximity with the indicator immediately adjacent to the switch or even built into it. In other cases, it may be that the indicators need to be logically arranged and provided with clear labels, as is the case with the laminated membrane-switch type shown in Figure 1. As the purpose of an indicator is to be seen, design considerations must include ambient lighting levels, and the distance from which it will be viewed. Size, color, brightness and even shape are some of the selection criteria with most requirements being readily met by the wide variety of LEDs available today.

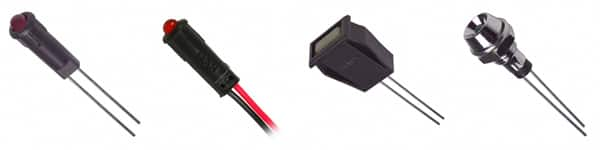

DigiKey offers LED panel indicators from a number of manufacturers. Lumex Inc. has a range of styles that embraces most of the types found in the types of measurement and process control equipment considered here. Examples of some of these can be seen in Figure 2. The first one, the SSI-LXH312ID is a 3 mm diameter, high-intensity, red LED in a black plastic-molded case with bezel, suitable for push-fit mounting in 4.32 mm diameter panel cutout. This is perhaps the most common style of LED, and one that almost every designer will be familiar with. Identical in style, dimensions and specification, but offered with 6” flying leads rather than wire terminals, is the SSI-LXH312ID-150. Round LEDs are very traditional, but the SSI-LXH072YD is an example of a 7 mm x 2.3 mm rectangular-format yellow LED that fits into a 11 mm x 5.3 mm panel cutout. While the first three panel indicators shown are designed to push-fit into the front of panels, they can equally well be fitted to a sub-panel located behind a laminated or glazed front panel. However the last style shown, the SSI-LXR1612GD, is a 3 mm diameter green LED that is clearly intended for external use as it features an attractive chromed-finish bezel. It has a metal threaded body that fits into a 6.2 mm diameter panel cutout and is retained by a nut.

Figure 2: Various styles of Lumex LED panel indicators available from DigiKey (part numbers, left to right: SSI-LXH312ID, SSI-LXH312ID-150, SSI-LXH072YD and SSI-LXR1612GD).

Data readouts using bar and character indicators

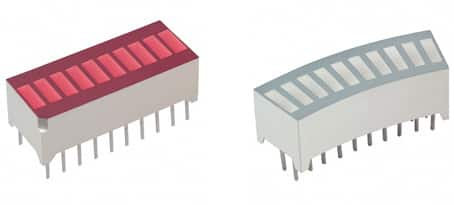

As discussed in the earlier part of this article, apart from simple threshold measurements, some data requires displays that are more complex. Multi-segment LEDs can readily address this requirement, either with bar or character displays. Again, DigiKey supplies devices from a number of manufacturers, but the LTA-1000HR 10-segment, red, bar graph display made by Lite-On Inc., shown in Figure 3, is typical of many such products. These devices are designed so they can be stacked end-to-end for longer displays, and can equally be arrayed in two dimensions if required to create a more complex display, such as in a 2-D bar chart. Bar graphs like this can display measured data in a pseudo-analog fashion, but can also be used to display a control setting. For example, two bar graph displays could be arranged side by side, with one showing the target setting and the other showing the actual reading. An interesting variation on the bar-graph type LED is a curved display made by Lumex Inc. (DigiKey part number SSA-LXB10SRW-10652), which again can be stacked end-to-end and could be used to mimic a dial-type meter.

Figure 3: Straight and curved 10-segment bar graph displays made by Lite-On and Lumex and available from DigiKey (part numbers: LTA-1000HR and SSA-LXB10SRW-10652).

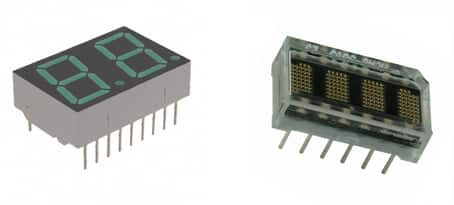

Character displays are typically used for digital meters to present measured data such as voltage, current, temperature or pressure. The number of digits will depend on the application but, for purely numeric data, a 2-character, 7-segment display like the HDSP-5623 made by Avago Technologies, shown in figure 4, may well provide the perfect solution. These displays can also be stacked side-by-side if four or more characters are required. This Avago device has 14.2 mm high characters formed from green LEDs, but red and yellow versions are also available from DigiKey. This size character is great for viewing from a distance or when a bold display is required. For some instruments, the smaller, 3.8 mm high characters, as found in the Avago HCMS-2902 4-character dot matrix display shown on the right in Figure 4, may be more appropriate. Being a dot-matrix type, this display can represent standard alpha-numeric characters, so may have applications where text information needs to be presented, e.g. simple messages like operator prompts or error codes.

Figure 4: Avago’s 2-digit, 7-segment numeric display and 4-character, dot-matrix display as supplied by DigiKey (part numbers: HDSP-5623 and HCMS-2902).

Ready to go display and control solutions

Finally, it is worth mentioning that not every measurement and process control application requires a custom designed display and control interface. DigiKey offers an alternative, off-the-shelf solution from Matrix Orbital. This product, shown in Figure 5 below, is designed to decrease development time by integrating simple input and display interfaces into a robust external enclosure. The ELK series of enclosure display comes in four versions, each combining the advantages of 20-character, 4-line LCDs with a 7-key tactile keypad and three tri-color LED indicators. All use LED backlighting for the LCD display, with different color options to ensure optimum readability in the target application environment. These enclosure display units have a threaded camera mount on the back and an attached USB cable, so they can be easily tied into any application and placed in the optimum location for ease of viewing and control operation.

Figure 5: Matrix Orbital’s enclosure display series.

Summary

This article has looked at display requirements across a range of industrial data acquisition and measurement systems, from simple threshold indicators or readouts of temperature, or pressure, through to more sophisticated gauges and bar-graph type displays, where LEDs are still preferred over LCD and other display technologies. It has reviewed the types of LED available and the considerations of size, color, brightness and other parameters that contribute to an effective and ergonomic solution in these types of application. The article has referenced specific products available through DigiKey from various manufacturers, both basic components for original designs (Lumex, Lite-On, and Avago) and a ready-to-go display solution from Matrix Orbital.

References:

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国