Flexible Power for Versatile Micros

投稿人:DigiKey 欧洲编辑

2013-01-08

Small, flexible, low-cost but high-performance microcontrollers, and the off-the-shelf boards built around them, are revolutionizing the world of electronics design for small systems. Products such as the Microchip PIC16, the Atmel AVR and Texas Instruments MSP430, and ready-made modules based around these and similar microcontrollers such as the Arduino and Basic Stamp, provide a range of flexible, programmable I/Os that lend themselves to a wide variety of different applications.

Many of these systems are powered by batteries, which have a strongly variable output voltage as they discharge. For example, the voltage output by a rechargeable lithium-ion battery will typically fall as it discharges from 4.2 V to around 3 V, with a wide plateau in the 3.5 V region. This is where most of the stored power will be delivered.

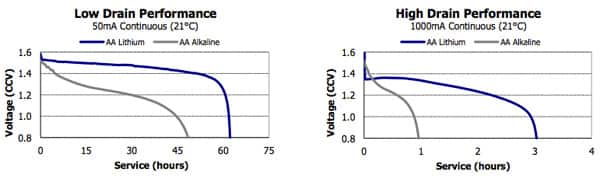

Alkaline cells, such as the ubiquitous AA cells, have their own discharge profile, with a voltage that drops from the nominal 1.5 V to around 1.2 V close to full discharge. The voltage output also depends heavily on the drain profile. AA batteries, when subjected to a high drain current demand, will generate a lower voltage than one that feeds a system that requires just a trickle of current. As these cells are generally used in paired or quad arrangements, the effective output voltage is higher across the range – but also highly variable.

Figure 1: The discharge profile for typical AA alkaline batteries (Source: Energizer).

Typically, low-power microcontrollers have input voltage requirements that range from 1 V to 3.3 V, depending on the process technology they employ. New-generation microcontrollers will typically have a lower input voltage requirement of 1.8 V or less. Some have flexible voltage inputs as they employ their own on-chip regulators, but it can make sense to have an external regulator deliver a fixed voltage as, being a dedicated device, it will generally offer higher efficiency. An on-chip may ‘burn’ a large proportion of the unwanted energy from a higher-voltage supply as heat – reducing the effective life of the battery pack.

The simplest regulator, and one that is often the best choice where low-noise performance is critical, is the low-dropout (LDO) regulator. Unfortunately, these are relatively inefficient designs when the input voltage is much higher than the output – which will happen with a pack of four AA cells that are fully charged. When providing the power to a microcontroller, the low-noise behavior of the linear circuitry-based LDO is generally unnecessary. Any on-chip analog functions will be protected from noise, as the strongest interferer is likely to be the digital circuitry being clocked at high frequency. As a result, a switched-mode DC/DC converter is generally the best choice, and manufacturers have responded with high-efficiency switching regulators designed specifically for low-power microcontroller-based systems.

Given that the most common usage model is to have a battery pack generating a higher voltage over almost the entire discharge curve than the requirement of the microcontroller or external memory voltage, designers will typically settle on a step-down or buck regulator as their main choice. Buck-boost converters that can switch between step-down and step-up operation are sometimes used in systems based on just one or two AA cells. However, the current consumption can go up dramatically when in step-up mode at the point where the cells are almost completely discharged. So the additional complexity and cost of the buck-boost topology does not necessarily pay off in terms of extended battery life.

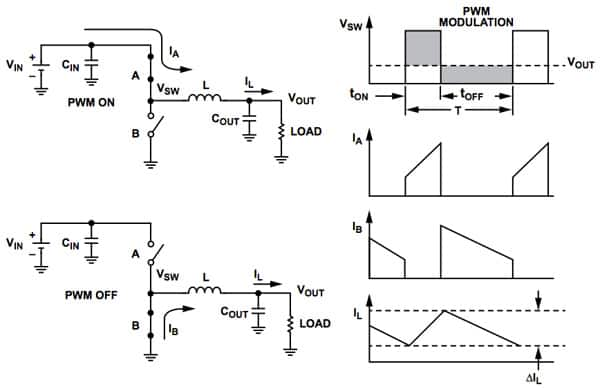

Figure 2: Topology of a typical buck converter and its current and voltage profiles (Source: Analog Devices).

The typical buck regulator design comprises two switches, usually implemented using power field-effect transistors (FETs) together with two capacitors – one on the load side and the other on the voltage-source side – and an inductor. The switches are connected from voltage-in to ground, with the output taken from the node between the two switches. To avoid the wasted energy of shoot-through, the switches are operated in such a way that only one is open at any one time. There are two phases to the buck regulator’s cycle. During the first phase, the lower switch is open such that current from the battery pack is allowed through to the load, connected in series with the inductor. Current gradually increases while there is a positive voltage across the inductor. The first switch is opened and the switch to ground shut. The inductor continues to source current, this time from ground, and the current falls – thanks to a negative voltage across the inductor – until the switch is opened ready for the next cycle. The capacitor on the output side ensures the voltage is kept as close as possible to the level needed by the load.

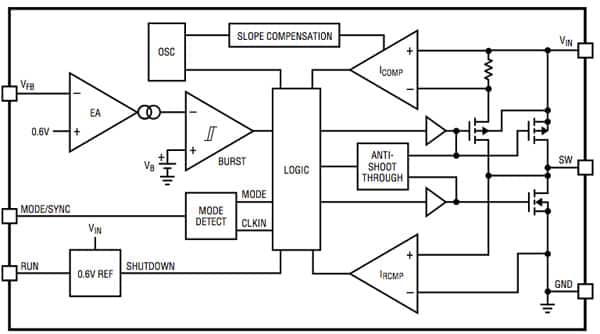

Figure 3: Architecture of a typical buck converter (Source: Linear Technology).

Control over the switching cycle is generally implemented by pulse-width modulation (PWM). This holds the switching frequency constant but varies the length of time that switches are held shut to control the output voltage. The longer the switch is shut, the longer the pulse and the higher the voltage that is developed at the load. Average power is a function of the duty cycle of the pulse – its ratio of on-time to off-time.

Although a PWM-controlled converter offers higher efficiency than an LDO, it tends to waste energy when the load’s demand for power is light. Many battery-powered microcontrollers spend a large proportion of their time asleep or in suspend mode, which will reduce the power demand to a very low level. So, for much of the time, the PWM-based regulator is potentially operating in its least-efficient state. At high input voltage and very low current, the efficiency of a typical switched-mode buck converter can drop from 80 percent to less than 10 percent.

The drop in efficiency is largely caused by the overhead of the regulator itself, continually switching at a frequency of a megahertz or more, but developing very little current at the load on each switching cycle. For this reason, a number of buck converters aimed at these systems implement a power-save mode. This mode develops a higher output voltage – generally around 1 to 2 percent above nominal. At this point, the PWM controller shuts down or goes into idle mode.

During idle mode, the output capacitor will gradually discharge until the output level falls back to the nominal PWM regulation voltage. This forces the controller to its next power-save cycle during which it drives the inductor and, with it, the output voltage to the power-save level, at which point the controller goes back into idle mode. This will continue until the load current increases to the point where the PWM controller reactivates and goes back to normal behavior. Because the effective frequency of operation changes based on the rate of voltage decline on the load side, the power-save mode can be regarded as a form of pulse-frequency modulation (PFM). If a more stable voltage output is required during low-power states, buck converters that implement a form of power-save mode can often be overridden by driving a control pin, at the cost of reduced efficiency.

One example of a DC/DC converter that implements features such as power-save mode is the Texas Instruments TPS6229x. Optimized for battery-powered portable applications, the device provides up to 1000 mA output current from a single lithium-ion cell. With an input voltage range of 2.3 V to 6 V, the TPS6229x operates at 2.25 MHz fixed switching frequency and enters power-save mode at light load currents to maintain high efficiency over the entire load current range. It has a mode pin to force it out of power-save mode for low-noise operation. In shutdown mode, the current consumption is reduced to less than 1 μA.

The Analog Devices ADP2108 is designed to operate with a range of power sources, including lithium-ion, alkaline, and nickel metal-hydride cells across a 2.3 V to 5.5 V operating range. The maximum load current of 600 mA can be achieved across the full input voltage range and the device will enter power-save mode when current demand drops below 80 mA. The device has under-voltage lockout to prevent deep battery discharge, as well as soft-start to prevent input current overshoot at system startup. During shutdown, controlled by external logic, the input is disconnected from the input and draws less than 1 µA from the input.

The ISL8009A made by Intersil delivers up to 1500 mA of current and will generate output voltages down to 0.8 A from an input anywhere in the 2.7 V to 5.5 V range. The device can switch between PFM and PWM modes, or forced to remain in PWM mode for lower-noise operation. The device switches at a frequency of 1.6 MHz during PWM mode.

Linear Technology offers the LTC3542, which operates from a 2.5 to 5.5 V input and was designed for use with lithium-ion cells. Output voltage is adjustable anywhere from 0.6 V to the input voltage, providing high flexibility. Switching in PWM mode at 2.25 MHz to minimize the size of external passive components, the LTC3542 can synchronize to an external clock signal running from 1 MHz to 3 Hz, making it easier to adjust the noise profile of the device in the context of the complete system design. The pin used to control the input frequency can also be used to control the device’s low-power modes. The normal low-power operation is burst mode, which implements typical power-save mode behavior. For lower ripple noise at low current, typically below 60 mA, the pulse-skip mode can be used. In this mode, the regulator continues operation in PWM mode but will skip over pulses to avoid the overhead associated with switching operations. This has the benefit of requiring less output filtering but without the power-saving attributes of burst mode.

The MAX1920 from Maxim Integrated Products delivers up to 400 mA of current down to a voltage of 1.25 V at a peak efficiency of more than 90 percent. The control scheme for the device maintains PWM operation during light-load conditions. When delivering light loads, the high-side switch turns off after the minimum on-time to reduce peak inductor current to maintain low output voltage ripple with reasonable efficiency. The MAX1920 implements soft-start for higher-impedance input sources such as lithium and alkaline cells. Soft-start is implemented by starting with the current limit at 25 percent of its full current value, and gradually increasing it in 25 percent steps until the full current limit is reached.

National Semiconductor’s LM3671 is a 2 MHz step-down DC/DC converter that takes a voltage input from 2.7 V to 5.5V and delivers up to 600 mA current to the load. The device comes in number of versions – some with adjustable outputs from 1.1 V to 3.3 V and others with a fixed output voltage. The LM3671 switches automatically from PWM to PFM mode based on current demand.

Paying close attention to the requirements and typical behavior of flexible microcontroller-based systems, the buck regulators offered by semiconductor vendors provide designers with a range of options for power delivery, with an emphasis on portability and battery life.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国