Advanced ICs Simplify Accurate State-of-Charge Measurement for Lithium-Ion Batteries

投稿人:电子产品

2013-01-23

All energy-harvesting-based systems need energy storage for times when the energy cannot be harvested (e.g., at night for solar-powered systems). Rechargeable batteries — known as “secondary” cells to differentiate them from “primary” or single-use cells — are usually specified for this task.

For rechargeable batteries, however, battery management depends on the best possible measurement of what is known as the state-of-charge (SOC) of battery cells. For lithium-ion batteries, the characteristics of Li-ion cells complicate SOC measurement and can challenge engineers looking to maximize Li-ion battery lifetime. To simplify design of Li-ion battery management systems, engineers can leverage a variety of SOC measurement techniques supported in ICs from Atmel, Linear Technology, Maxim Integrated Products, STMicroelectronics, and Texas Instruments.

Battery SOC is defined as the percentage of charge remaining in a battery, and thus ranges from 0% to 100%. Because SOC measurement fills the same purpose as a gas gauge in an automobile, ICs that provide SOC measurement are typically called "gas gauge" or "fuel gauge" ICs.

SOC measurement underlines intelligent battery management systems. As SOC changes, battery management systems calculate optimum charging voltage and current values. Consequently, SOC measurement ICs are typically paired with battery charger ICs in designs or included as functionality within more comprehensive charge management and battery protection designs.

SOC measurements are used by the host system to manage power usage and by the application to notify users as battery charge becomes low. In electric vehicles, for example, SOC measurements are central to estimations of remaining range available to the vehicle and appear on the driver's display panel as a familiar fuel gauge and range estimate. Indeed, automotive applications require reliable SOC measurements to reduce "range anxiety" as drivers begin to accept these new types of vehicles.

In fact, reliable SOC measurement is essential for ensuring safety and maximizing battery life in rechargeable batteries in general and for Li-ion cells in particular. Poor estimates of SOC can result in over-charging and over-discharging, resulting in diminished battery performance and lifetime. Worse, uncontrolled charging can even give rise to battery breakdown, thermal runaway and even uncontrolled venting and explosion.

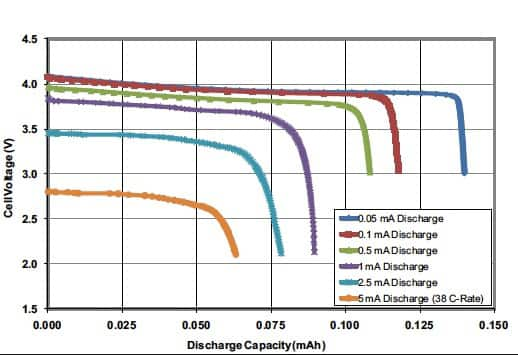

For Li-ion cells, however, accurate measurement of SOC is difficult at best. Li-ion cells maintain a near-constant voltage output across much of their discharge range (Figure 1). As a result, the common method of simply relating voltage measurements to charge remaining in the battery cannot be used for these cells.

As a result, determining SOC for Li-ion cells is largely a process of estimation and remains the subject of active research to find better methods for refining SOC estimates. For large, complex battery packs such as those used in electric vehicles, the need to maximize cost-efficiency of the battery requires very sophisticated SOC estimation methods based on neural networks, fuzzy logic, and adaptive filters. For many other energy harvesting applications, however, less complex methods based on current measurements, voltage measurements, or model-based methods provide adequate information about battery SOC needed for the application.

Current-based method

The current-based method tracks the change in charge remaining in the battery by measuring discharge and charge currents. In this method, called coulomb counting, the battery management system estimates SOC by calculating net increase and decrease in charge based on current measurement. Although this method is highly accurate in theory, the practical characteristics of circuits leave it prone to error, particularly over time. Uncertainties in current sensor accuracy, parasitics, and cell aging can introduce errors that accumulate over time, requiring periodic recalibration.

Because of this method's simplicity and relative accuracy, engineers will find current-based SOC measurement supported in a wide range of ICs. For example, the Linear Technology LTC2941 and LTC2942 feature dedicated coulomb counting circuitry. The LTC2942 infers charge flow by integrating voltage measurements of battery current taken across a sense resistor. The IC applies the differential voltage between SENSE+ and SENSE– to an auto-zeroed differential analog integrator to convert the measured current to charge (Figure 2).

In turn, a host controller reads the accumulated charge register (ACR), fed by a programmable prescaler. The ACR is incremented or decremented by one with each underflow or overflow of the prescaler, so integration time is effectively scaled by a factor M, programmable from 1 to 128. The device also includes a 14-bit sigma-delta ADC for use in monitoring battery voltage at SENSE-, enabling engineers to incorporate voltage-based methods for SOC estimation.

Voltage-based method

The voltage-based method measures battery voltage and relates that value to charge level. Here, the battery management system measures voltage of the battery either connected to an external load or in open circuit. Measurement of open-circuit voltage (OCV) can provide sufficiently accurate results, but requires special considerations.

For example, the flow of current in Li-ion cells results in a non-uniform distribution of ions in the electrolyte. This phenomenon, called the diffusion effect, can introduce errors in SOC estimation. As a result, battery management systems can improve SOC estimation by measuring battery OCV after the battery chemistry has had a chance to equilibrate, thus reducing the diffusion effect. Consequently, use of OCV for SOC estimation can be problematic in dynamic applications where fluctuating load currents result in voltage changes and related diffusion effects.

Although each method suffers some limitations, semiconductor manufacturers offer solutions that include on-chip hardware designed to support a combination of these methods for improving SOC estimates. During fluctuating current or high-current states, the coulomb counting method tracks net changes in SOC. During quiet periods, voltage-based methods including OCV measurement help correct errors that accumulated with coulomb counting.

Along with Linear Technology LTC2941/LTC2942 devices, engineers can find devices including the Texas Instruments BQ2700 and the STMicroelectronics STC3100 and STC3105 that include hardware features enabling engineers to use both coulomb counting and voltage measurements for estimating SOC more accurately.

The TI BQ2700 includes a dedicated fully differential delta-sigma coulomb counter circuit to measure charge and discharge current along with an ADC for voltage and temperature measurements. The BQ2700 automatically compensates the coulomb counter and ADC for offsets, so no user calibration or compensation are required.

At the heart of the STMicroelectronics STC3100 and STC3105, a coulomb counting circuit tracks SOC when the battery is charging or discharging at a high rate (Figure 3).

To enable engineers to manage power consumption, the STC3105 offers two power modes: active mode, where current is measured every cycle, and power-saving mode, where current is measured only every other cycle to conserve power.

The ST devices also include a 14-bit sigma-delta A/D converter, which is used for both voltage and current measurement. The STC3105 measures battery voltage every four seconds with an accuracy +/- 0.5% over the operating temperature range, allowing engineers to use these results to calculate SOC using OCV methods. To mitigate diffusion effects, the device includes a battery voltage relaxation timer. A host processor can check this timer to ensure that the battery has been in a quiescent state long enough to ensure more accurate SOC measurements.

Along with a 10-channel 12-bit sigma-delta ADC for cell voltage measurements, the Atmel ATmega406 provides a dedicated sigma-delta ADC for coulomb counting and offers different measurement modes intended to allow engineers to trade measurement accuracy for power consumption.

In the device's Instantaneous Current Conversion (ICC) mode, the ADC generates a 13-bit signed result in about 3.9 ms, providing a method to measure battery voltage and discharge current at about the same time when calculating impedance. The device's Accumulated Current Conversion (ACC) mode is intended to provide high accuracy results even while the target application is running and drawing current from the battery. Although the conversion time is much longer (128-1000ms), the device provides an 18-bit result. Finally, the device's Regular Current Condition (RCC) mode offers the same accuracy and conversion time as ICC mode, but operates in conjunction with the MCU's sleep modes to provide results during application sleep modes and only when current levels rise above a selectable threshold.

Engineers can also find ICs such as the Maxim DS2786 that estimate SOC based on internal algorithms that combine coulomb counting and OCV measurements. While the cell is charging or discharging, the DS2786B measures net charge flow. During quiet periods, the DS2786B waits for a set relaxation period and then adjusts its SOC estimate from coulomb counting using an OCV model stored in device EEPROM, along with cell characteristics and application parameters. The device's EEPROM is constructed with a SRAM shadow, allowing the host to overwrite OCV voltage profile and scale factors to accommodate diverse cell types (Figure 4).

Model-based methods

IC manufacturers also provide SOC measurements based on proprietary methods built around models of Li-ion cell performance. For example, Maxim standalone fuel-gauge devices such as the DS2780 bases SOC estimates on a variety of cell and circuit characteristics including temperature, load current, and charge termination point. The device uses an integrated temperature sensor to measure battery temperature with a resolution of 0.125°C every 440 ms.

For current measurement, the DS2780 continually measures the current flow into and out of the battery during active mode by measuring the voltage drop across a low-value current-sense resistor. Engineers can correct for temperature-dependent variations in the current-sense resistor by programming the value of a sense resistor temperature coefficient.

Furthermore, engineers can program an accumulation bias register to account for typical sources of error in coulomb counting due to battery self-discharge and static offsets. Finally, these measured values are combined with stored characteristics as inputs to on-chip algorithms designed to estimate SOC and associated results (Figure 5).

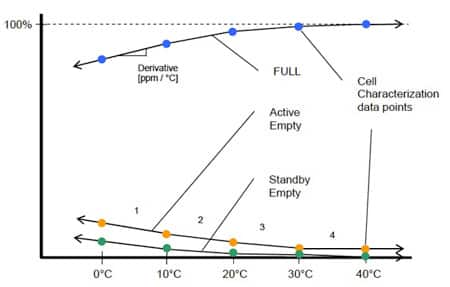

Underlying these algorithms, the DS2780 stores cell characteristics using a piece-wise linear model comprising three curves – full, active empty, and standby empty – each constructed with four line segments (Figure 6). Each curve defines variations in its respective state of charge point due to temperature. The DS2780 processes measurement and cell characteristics every 440 ms and stores the results as a function of the present temperature in on-chip registers.

Maxim's MAX17040, MAX17048, and MAX17049 use a Li-ion battery-modeling scheme called ModelGauge, which measures SOC continuously over widely varying charge and discharge operation. Here, the algorithm determines SOC by simulating the internal nonlinear dynamics of a Li-ion battery based on the battery's impedance and rate of chemical reactions in the battery.

The Maxim algorithm eliminates the need for an external current-sense resistor and for battery relearn cycles. In this approach, the device draws on a custom model that is built by characterizing the battery at multiple discharge currents and temperatures. The MAXIM ModelGauge ICs come with a preloaded model that is sufficient in many cases.

Texas Instruments uses a model-based SOC algorithm called Impedance Track with its BQ27541, BQ20Z75, and BQ34Z100 gas gauge ICs. To improve SOC accuracy, the TI Impedance Track algorithm draws on three types of information: chemical depth of discharge (DOD), electrical battery resistance, and external factors including load and temperature.

The algorithm uses OCV measurements during relaxed voltage states and computing DOD based on battery-technology-specific tables stored in flash. Engineers can set up Impedance Track devices for a particular battery chemistry by using firmware available from TI. Battery resistance values are updated during discharge, but the algorithm delays resistance update to reduce distortions from transients associated with response to a load.

Temperature values are critical to the algorithm but temperature measurement is difficult to obtain because temperature changes significantly during the course of a discharge. Consequently, the algorithm predicts future temperature to allow temperature correction of battery impedance near the end of discharge. Here, the algorithm collects temperature dependence data during discharge and uses the results, which include a heat exchange coefficient and a thermal time constant, to update its thermal model parameters. During relaxation periods, the algorithm also measures outside temperature and uses the results to define a temperature profile model based on the present temperature and extending through the end of the discharge.

Conclusions

Determining SOC in Li-ion batteries can be challenging at best and typically relies on highly sophisticated methods to ensure accuracy in complex battery management systems used in electric vehicles. For many applications, however, simpler algorithms based on current measurement, voltage measurement, cell-characterization models or combinations of each offer sufficiently accurate results. Specialized fuel-gauge ICs implement these methods in many variations, offering engineers a breadth of options needed to easily implement designs with battery management systems able to provide accurate estimates of Li-ion battery SOC.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国